Contact Our Team

Please feel free to contact us

CALL US: +91 8108016334

MAIL US: trishalastainless@gmail.com

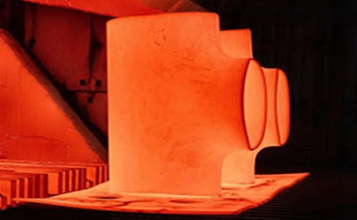

Stainless Steel Fittings

Features Of Stainless Steel Pipe Fittings

Corrosion resistance

Limited chemical reactivity

Highly Cost Effective

Easy To Maintain

Specification List Of SS Fasteners

| Specifications | Stainless Steel Fittings |

|---|---|

| Manufacturer Dimension | ANSI/ASME B16.28/ ASME/ANSI B16.9/ MSS-SP-43/ ASME/ANSI B16.11 |

| Thickness Chart | Schedule 5S/ Schedule 10S/ Schedule 40S/ Schedule 80S/ Schedule 160S/ Schedule XXS |

| Types | Elbow Fittings (45 Deg, 90 Deg, 180 Deg, Long Radius & Short Radius, 1D, 1.5D, 3D, 5D) Tee Fittings ( Reducing, Equal, Unequal, Lateral, Straight, Barred, Split) Reducer Fittings (Concentric And Eccentric) End Cap Fittings (Square/ Round/ Rectangular/ “U” Shape/ “I” Shape/ Oval End) |

| Forging Methods | ButtWeld And Welded Or Seamless |

| Bending Radius | R=1D/ 2D/ 3D/ 5D/ 6D/ 8D/ 10D or Custom |

| Surface Treatment | Sand blasting/ Sand Rolling/ Sand Blasting |

| Sizes | Buttweld ½" NB to 120" NB Seamless ½” to 24” Welded ½” to 120” Two Joint / Two Halve Fittings 6” to 48” |

| Our service | Nace Mr 01 75 Sour Service Impact Test As Per Ug 84 Macro Structure Analysis Hydrogen Induce Cracking Test (Hic) Sulphide Stress Cracking Test (Sscc) Cryogenic Services (Cryo),hydrogen Services (H2) Helieum Leak Test Dye Peniterant Test (Dp) Magnetic Partius Test (Mp) Post Weld Heat Treatment (Pwht) Ultrasonic Test (Ut) Hydro Test, Etc. |

| Coating | Anti-rust Paint/ Zinc Plated/ Oil Black Paint/ Yellow Transparent/ Cold and Hot Dip Galvanized |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged/ Heat treated and machined |

Advantages Of SS Fittings

The end of the pipeline

The attachment of auxiliary equipment

A reduction in pipe diameter

Change direction of flow

Connect or joint pipes

Types Of SS Pipe Fittings

Equal Tee

Reducing Tee

Equal Cross

Reducing Cross

Concentric Reducer

Eccentric Reducer

Stub End

Pipe Cap

Pipe Bends

90 Deg Elbow

45 Deg Elbow

180 Deg Elbow

Short Radius Elbow

Long Radius Elbow